Grain Combine Harvesters: working principle, function and precautions for use Jul, 21, 2024

Grain combine harvesters stand as indispensable tools in modern agriculture, seamlessly integrating harvesting, threshing, cleaning, and conveying operations into a single, efficient process. These remarkable machines have revolutionized grain harvesting, dramatically enhancing labor productivity and minimizing losses. Their versatility extends to a wide range of crops, including wheat, rice, corn, and soybeans.

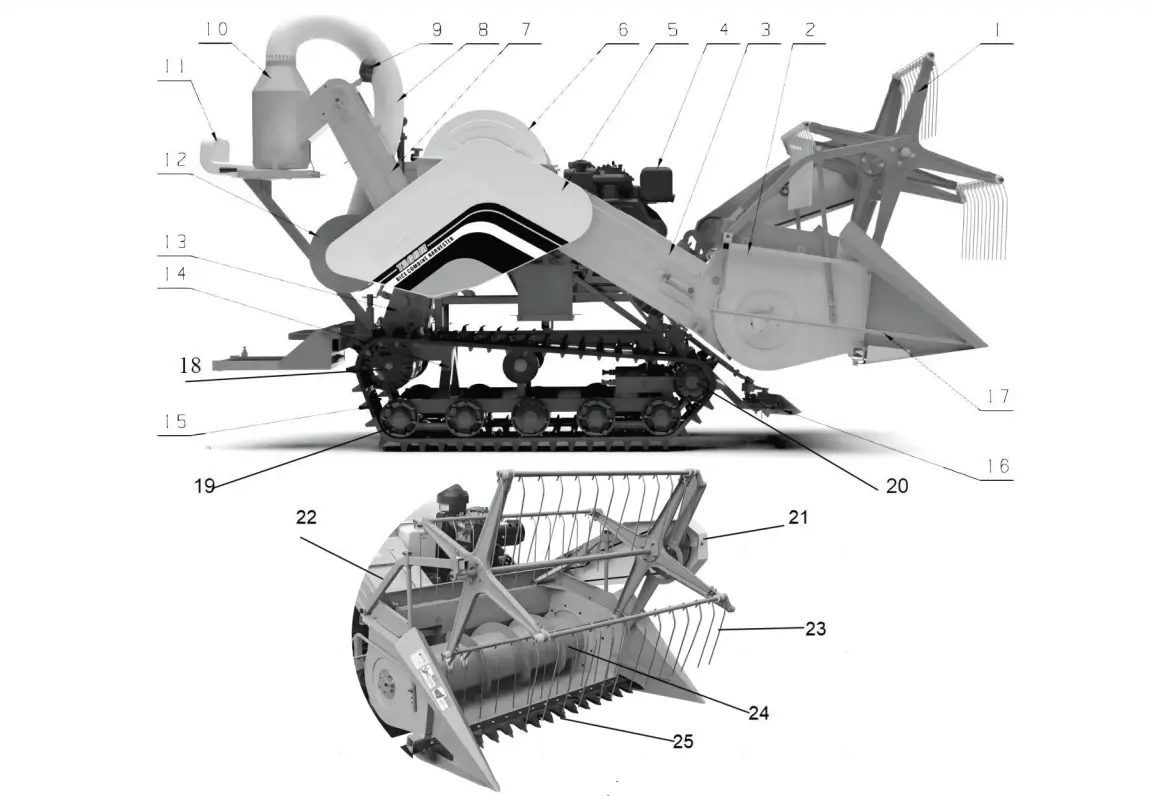

- Structural Components of Grain Combine Harvester

- Working Principle of Grain Combine Harvester

- Precautions for Use of Grain Combine Harvester

- Maintenance of Grain Combine Harvester

Structural Components of Grain Combine Harvester

Grain combine harvesters are intricate machines composed of several key components that work in harmony to achieve their purpose:

- Walking Gear: The foundation of the harvester, the walking gear provides support and mobility. It comprises a frame, walking mechanism, and steering mechanism. The frame ensures structural integrity, the walking mechanism propels the harvester, and the steering mechanism controls its direction. Common walking gear types include wheeled and tracked designs.

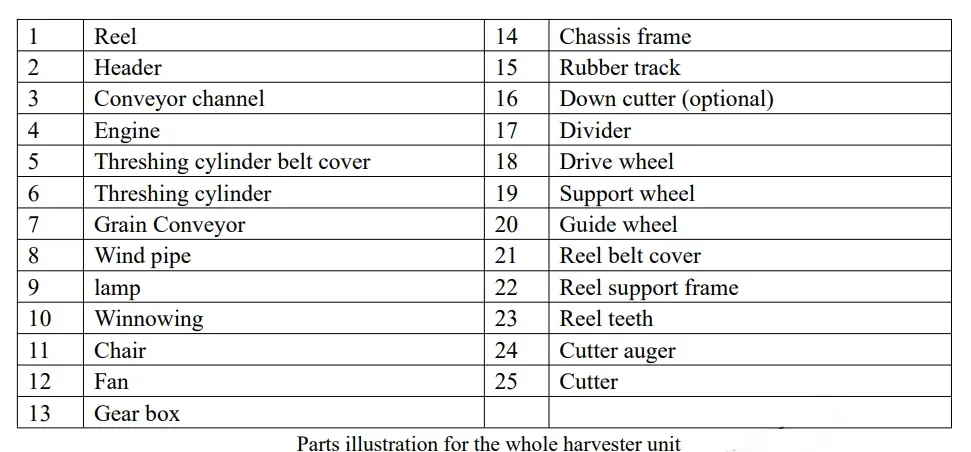

- Header: The header spearheads the harvesting process, responsible for cutting and gathering the crop. It consists of a cutterbar, reel, and feeder. The cutterbar severs the crop, the reel guides the cut crop to the feeder, and the feeder evenly introduces the crop into the threshing unit.

- Threshing Unit: The heart of the harvester, the threshing unit separates the grains from the straw. It includes a threshing cylinder and separator. The threshing cylinder mechanically detaches the grains, while the separator initially removes some impurities.

- Cleaning Unit: The cleaning unit refines the grain by removing finer impurities. It comprises sieves and a fan. The sieves utilize openings of different sizes to separate grains based on size, while the fan expels lighter impurities like chaff and dust.

- Grain Tank: The temporary repository of the cleaned grains, the grain tank holds the harvested grains until they are ready for unloading.

- Engine: The power source of the harvester, the engine provides the necessary energy for all operations. It powers the walking gear, header, threshing unit, cleaning unit, and grain tank.

- Control System: The harvester’s command center, the control system allows the operator to manage its functions. It consists of joysticks and dashboards. The joysticks control harvesting operations, while the dashboards display essential parameters.

Working Principle of Grain Combine Harvester

Grain combine harvesters operate through a series of integrated processes to efficiently harvest, thresh, clean, and transport grains. The fundamental working principle can be summarized as follows:

- Harvesting: The crop is cut by the header’s cutterbar and conveyed to the feeder.

- Threshing: The crop is pushed into the threshing unit by the feeder, where the threshing cylinder separates the grains from the straw.

- Preliminary Cleaning: The grains and impurities pass through the separator, which initially removes some debris.

- Cleaning: The grains and remaining impurities enter the cleaning unit, where sieves with different sized openings further separate the grains based on size. A fan blows out lighter impurities like chaff and dust.

- Grain Conveying: The cleaned grains are transferred to the grain tank, which holds them until they are ready for unloading.

- Transporting: The grain tank conveys the harvested grains to the grain storage using a conveyor or auger.

Precautions for Use of Grain Combine Harvester

To ensure safe and efficient operation of grain combine harvesters, follow these precautions:

- Read the Manual: Before using the harvester, carefully read the instruction manual to understand its operation and safety guidelines.

- Inspect and Adjust: Conduct a thorough pre-operation inspection, checking tire pressure, fluid levels, cutterbar sharpness, and other crucial components. Make necessary adjustments as needed.

- Choose Suitable Terrain: Operate the harvester on flat and level fields, avoiding areas with ditches, obstacles, or excessive slopes.

- Control Speed: Maintain a controlled speed that matches the field conditions and crop density to prevent the harvester from bouncing or overloading.

- Clear Debris: Regularly clean debris from the header, threshing unit, cleaning unit, and grain tank to maintain optimal performance and prevent blockages.

- Prioritize Safety: Always prioritize safety. Wear protective gear, operate the harvester from a designated safe zone, and avoid working in hazardous conditions.

- Regular Maintenance: Schedule regular

Maintenance of Grain Combine Harvester

The grain combine harvester is a precision machine that requires regular maintenance to ensure it is in good working condition. The main contents of maintenance include:

- Regularly check and replace lubricants such as engine oil and lubricating oil.

- Clean dust and impurities in the engine, travel device, threshing device, cleaning device and other parts.

- Check and adjust the blades, feeders and other parts of the header.

- Check and tighten bolts, nuts and other connectors.

By following these guidelines, you can ensure the safe, efficient, and productive operation of your grain combine harvester, maximizing its contribution to your agricultural endeavors.